HOW IS JEWELRY STAMPED: WHY STAMPED JEWELRY IS POPULAR

By: Leslie H.

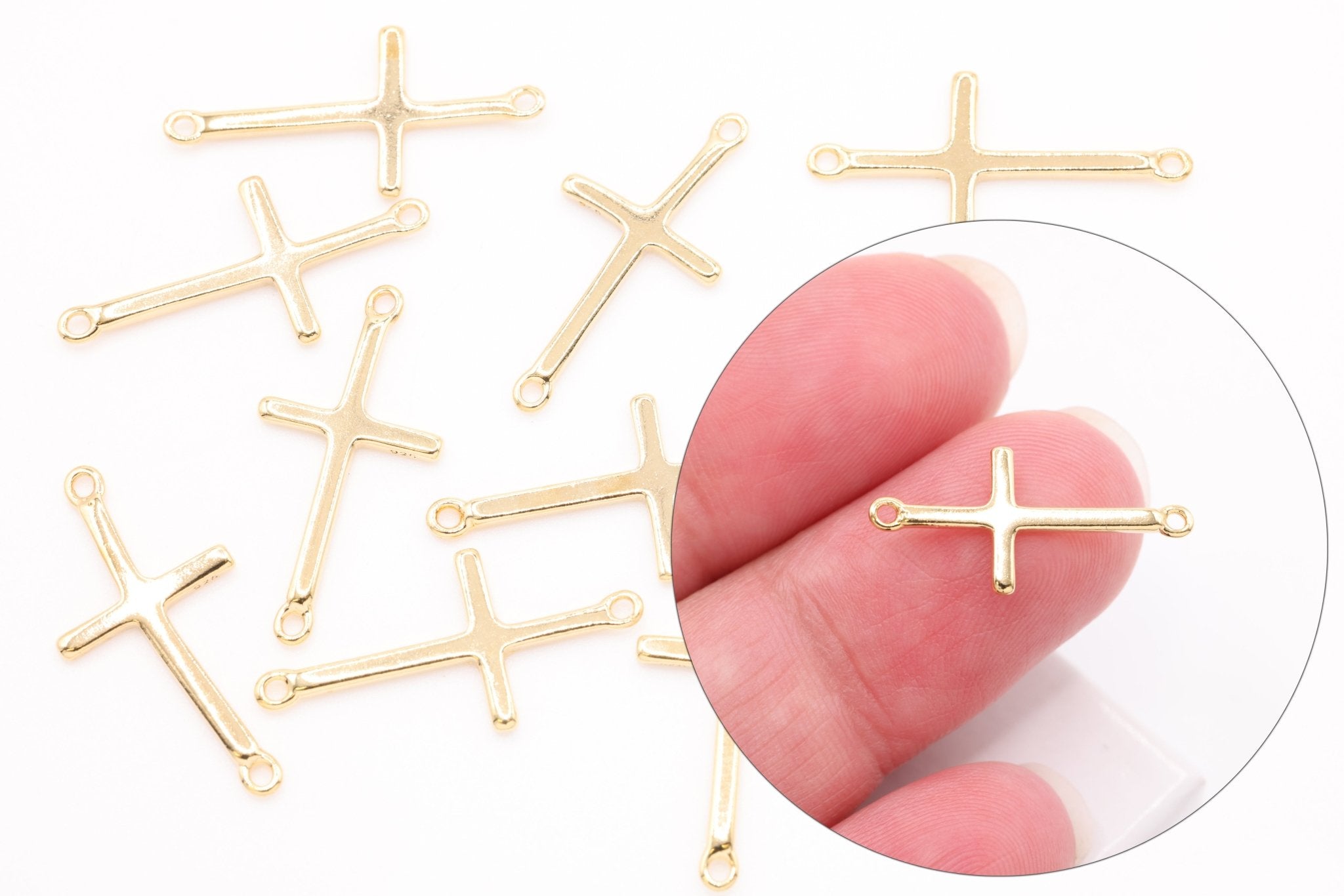

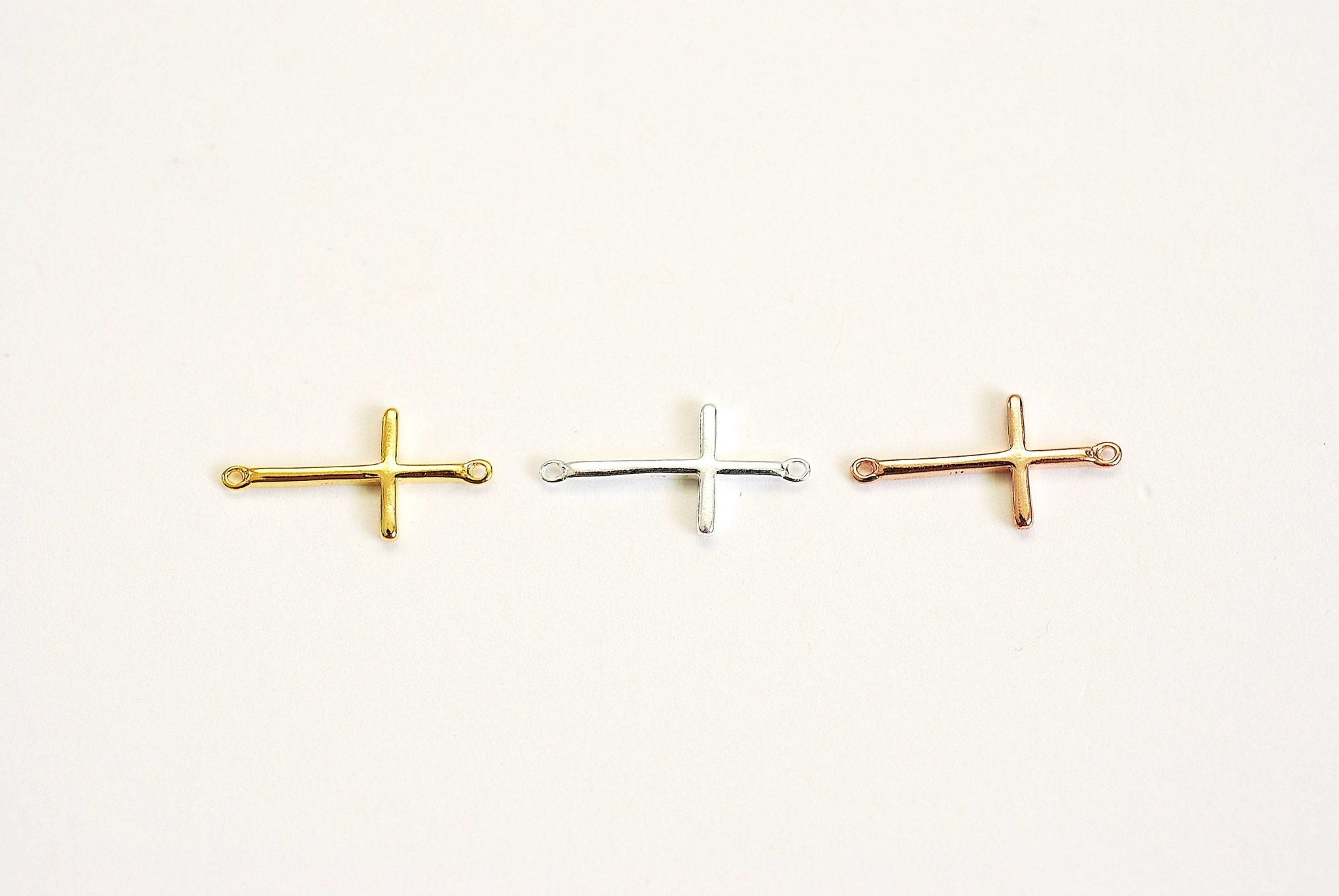

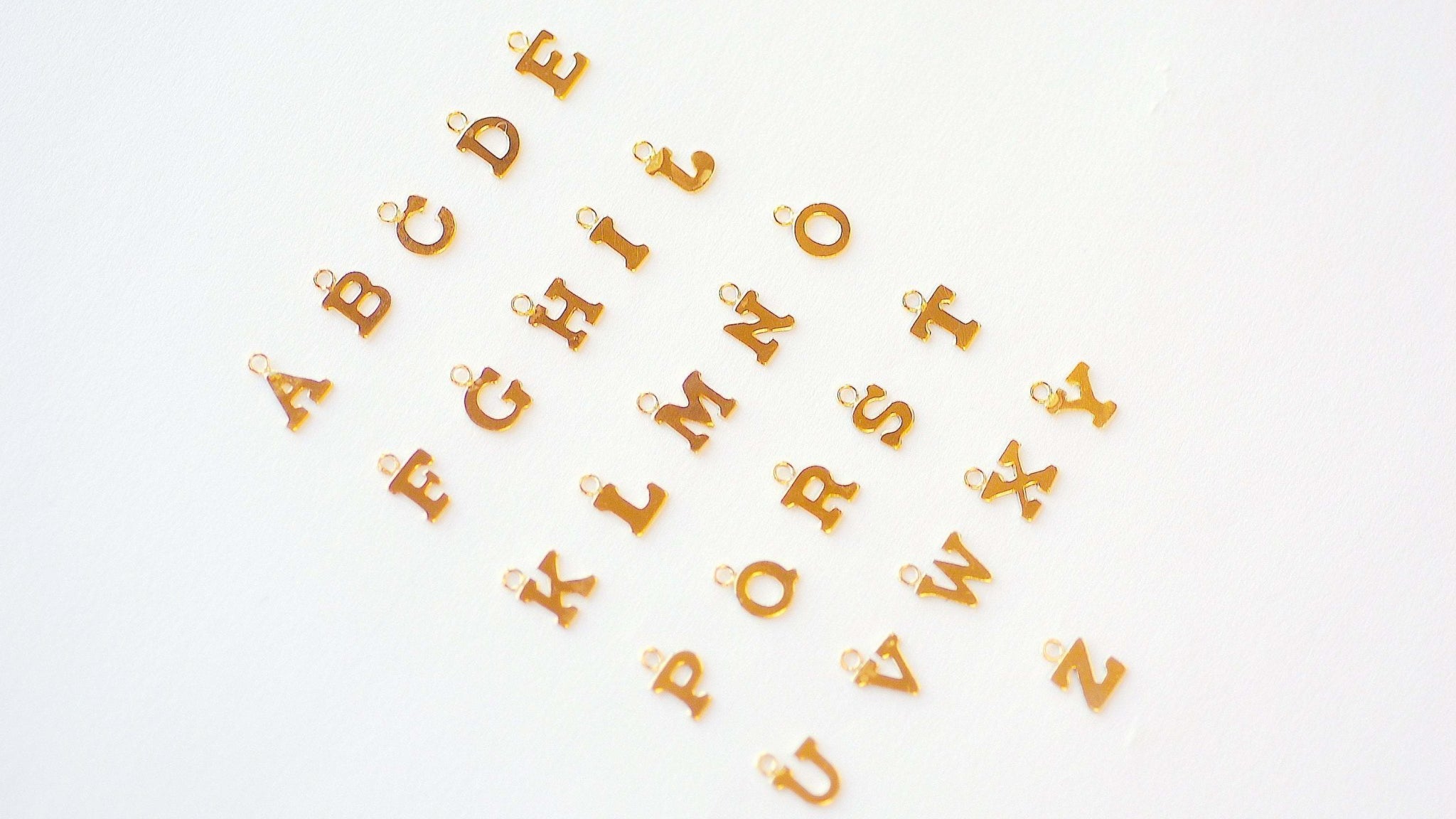

Jewelry stamping is a manufacturing process used to create designs on sheet metal. This method involves pressing a stamp or die with a specific design onto a sheet of metal to imprint the design onto the surface. The process can be used to create a wide range of jewelry items, including charms, findings, earrings, and many more jewelry pieces.

1. Design Creation: The first step involves designing the stamp or die. This can be done manually by a craftsperson or with computer-aided design (CAD) software. The design must be planned to ensure that it will create the design and structural integrity of the jewelry piece.

2. Die Making: Once the design is finalized, a die (a hardened piece of metal with a raised design) is created. This die will be used to stamp the design onto the metal sheet. The die-making process requires precision, as the quality of the die directly affects the final product's detail and quality. There will be a male and female portion of the die. The male portion will strike into the female portion to stamp the pieces through the metal sheet.

3. Metal Preparation: Before stamping, the metal sheet is prepared. This usually involves cutting the metal into manageable pieces and ensuring the surface is clean and free of imperfections. The type of metal used can vary, including gold, silver, copper, brass, and more, depending on the desired finish and properties of the final product.

4. Stamping: The prepared metal sheet is then placed in a stamping press, where the die is pressed into the metal with significant force. This imprints the design onto the metal. The pressure must be carefully controlled to ensure a clear, precise design without damaging the metal.

5. Finishing Touches: After stamping, the pieces undergo finishing processes. This can include trimming excess metal, polishing, and adding any necessary details like loops or engravings.

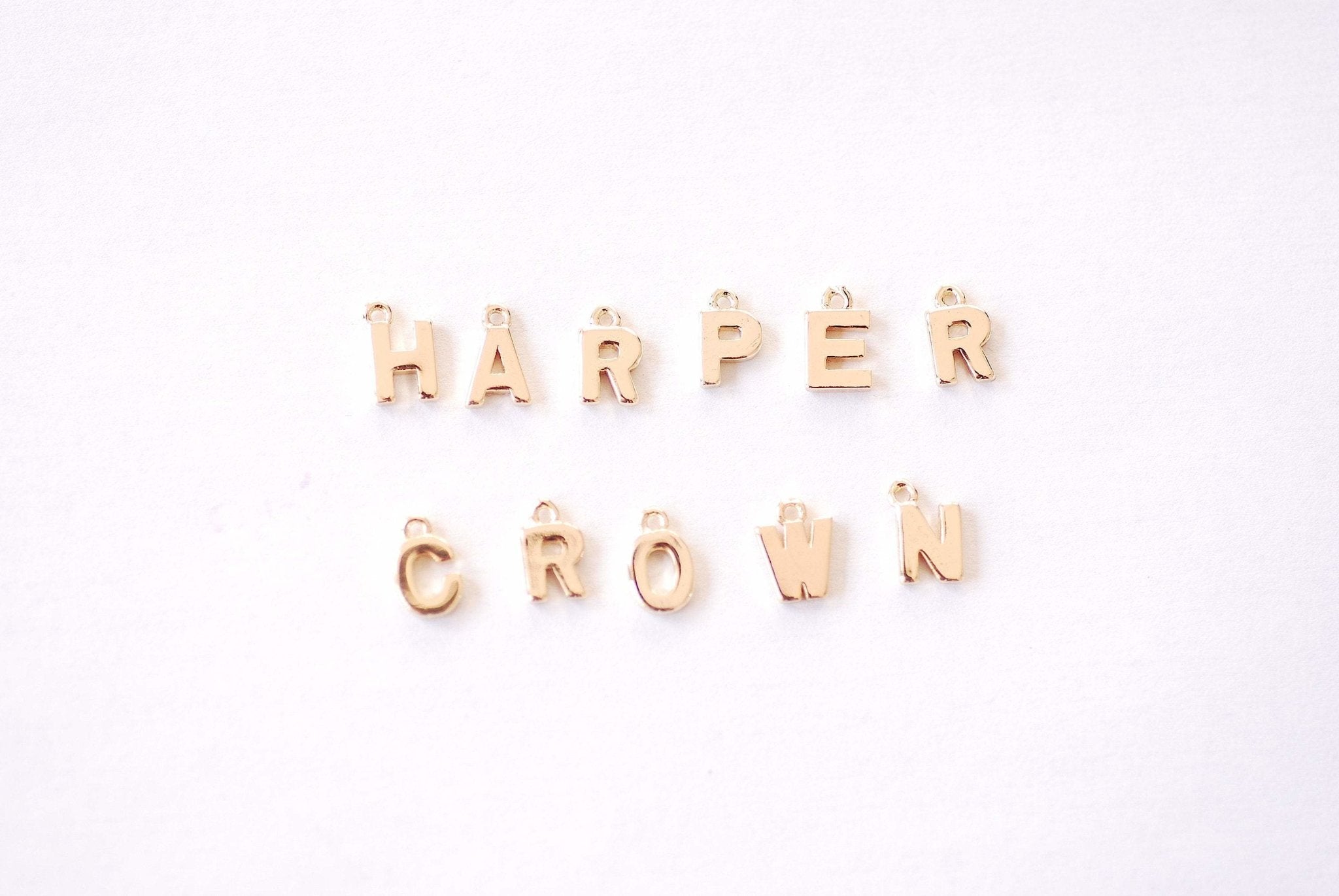

SHOP Wholesale Stamped Charms & Jewelry

Jewelry stamping offers several advantages over other manufacturing methods:

Efficiency: Stamping allows for the rapid production of large quantities of jewelry, making it an efficient method for mass production.

Consistency: Each piece is stamped with the same die, ensuring uniformity and consistency in design across multiple pieces.

Versatility: A wide variety of designs can be achieved, from simple shapes to complex patterns.

Cost-effectiveness: Stamping is relatively cost-effective, especially for producing large quantities, making it a popular choice for both high-end and more affordable jewelry lines.

Whether it's a simple silver pendant or an intricate gold bracelet, stamped jewelry holds a charm that celebrates both innovation and tradition in the world of jewelry making.

![Gold Filled Beaded Ring, Gold Silver Stacking Ring, Hammered Bead Ring, Gold Dot Ring Midi Ring Gold Filled Flat Beaded Ring Minimalist [30] - HarperCrown](http://www.harpercrown.com/cdn/shop/products/gold-filled-beaded-ring-gold-silver-stacking-ring-hammered-bead-ring-gold-dot-ring-midi-ring-gold-filled-flat-beaded-ring-minimalist-30-568879.jpg?v=1634159908&width=2048)

![Gold Filled Beaded Ring, Gold Silver Stacking Ring, Hammered Bead Ring, Gold Dot Ring Midi Ring Gold Filled Flat Beaded Ring Minimalist [30] - HarperCrown](http://www.harpercrown.com/cdn/shop/products/gold-filled-beaded-ring-gold-silver-stacking-ring-hammered-bead-ring-gold-dot-ring-midi-ring-gold-filled-flat-beaded-ring-minimalist-30-638411.jpg?v=1634159908&width=2048)