For years and years, gold has been used in the construction of temples, the making of ornamental weapons, and now, the manufacturing of gold accessories we wear. Jewelry making is an ancient art, and we want to bring that art to you. Over the centuries, the gold varieties have expanded to include allowances for different purposes. Different customer sets, storefronts, and creative ideas require different varieties of gold. From durability, color, to price, the options of gold are endless and, in this post, we’re going to look at the different gold medal types and the purposes for which they should be used.

When considering your own jewelry manufacturing, you want to think about the wearability, demographic, and purpose you aim to design for. Different levels of the metal are good for different uses and something really fantastic about gold is that there is a level of gold for each profit threshold and margin, allowing all different kinds of companies to use it for manufacturing. When people hear “gold” they might think it is out of their budget, but most of the time, it’s as affordable as you need it to be. Another thing to consider, as you read, is to use the correct durability for your purpose. The mix of metals in your gold piece can be a determining factor of how durable that piece will be.

The Elemental Metal

Gold, the element, means 24k gold. This is the purest form of gold and is actually not used by itself in very many applications. Pure gold is very pliable when used on its own, making any jewelry produced with it completely bendable. Pure gold is mostly only used current day in gold leaf and gold sheeting. Gold foil can be used in designs and productions to give an ornate ornamental effect. Most nail salons even keep the gold foil on hand to use on nail designs!

Yellow Gold Alloys

When people started to use gold in their jewelry making more routinely, they realized that the royal jewelry that was pliable and solid elemental gold would no longer suffice. Instead, they learned to start mixing pure gold with Zinc and Silver to make the metal more durable, and equally important, less expensive. The gold jewelry was suddenly a consumer piece after this discovery because it was actually long-lasting, wearable, and cleanable. Still a more expensive option, but starting to become for durable and wearable.

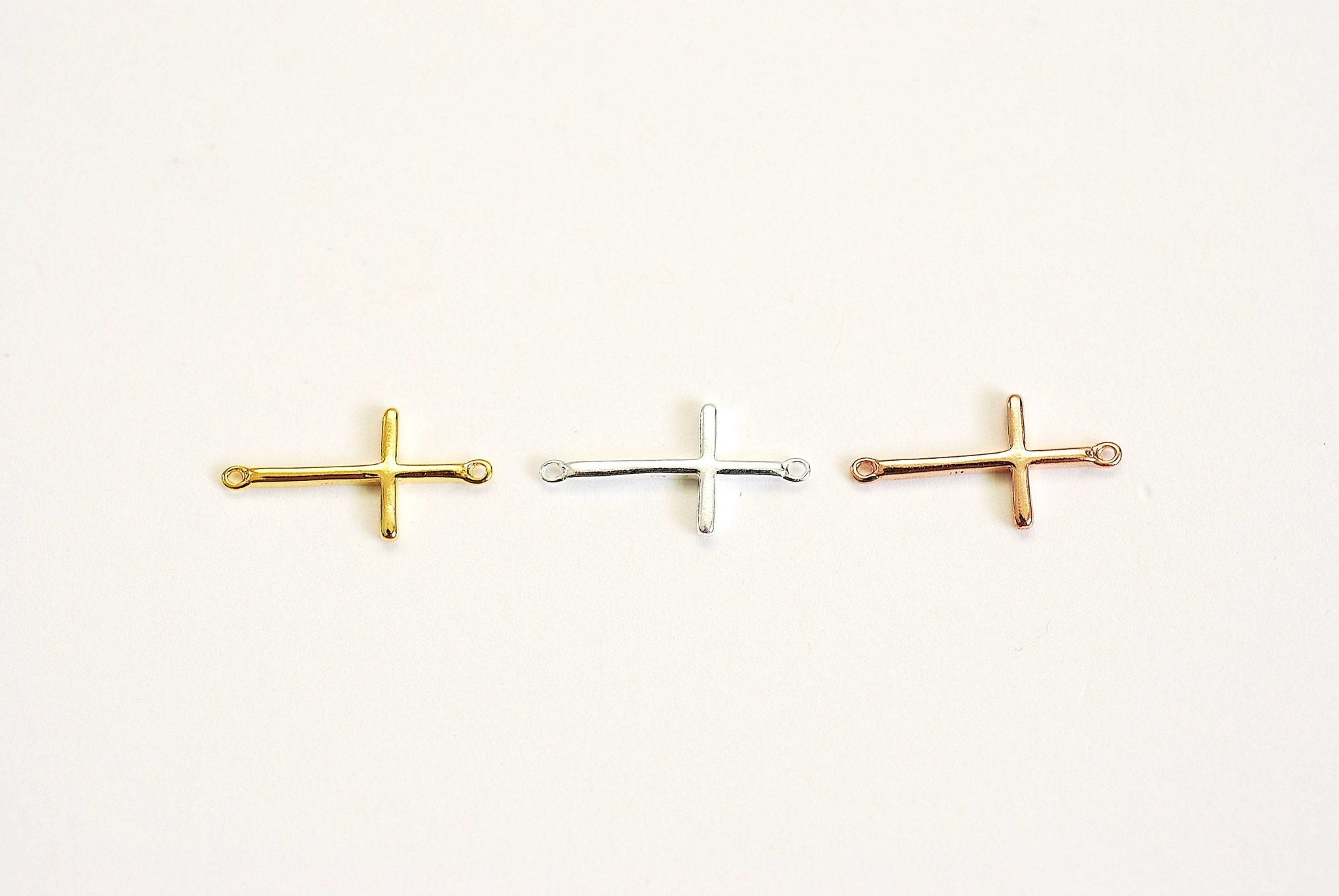

White Gold Alloy

Sometimes, the application or customer will call for a lighter-colored gold. White Gold appears mostly silver, but with added durability. Sterling silver can be soft and tough to work with for some purposes, so it can be much better for the piece to use a white gold alloy. This alloy is produced by adding Nickel to the solution. White gold is a great material and can be maintained by having the piece of jewelry re-Rhodium plated every so often so that it does not oxidize back to yellow gold.

Rose Gold Alloy

Rose Gold Alloy has become so popular in the last few years! This solution is made by adding amounts of copper to the yellow gold alloy and your result will be varying shades of pink-hued gold. Playing with the ratios of these ingredients can help with the tone of the final product, but in any case, rose gold is becoming a new classic.

Brass

Brass is a low-cost but effective solution for further manipulating the color of the gold product. Brass has different configurations and is easy to work with, manipulate and change. Brass finishes, however, can show a seam where they are bound to the gold, but good products and quality work can make this seam undetectable. There are two kinds of brass: yellow brass and red brass. These two tones end up resulting in the above colors, the yellow gold alloy look, and the rose gold alloy look. Red brass (per the name) has a higher copper content, giving it a more rose-colored tint. The Red brass is 15% Zing and 85% copper, while the yellow brass is 33% Zinc and 67% Copper.

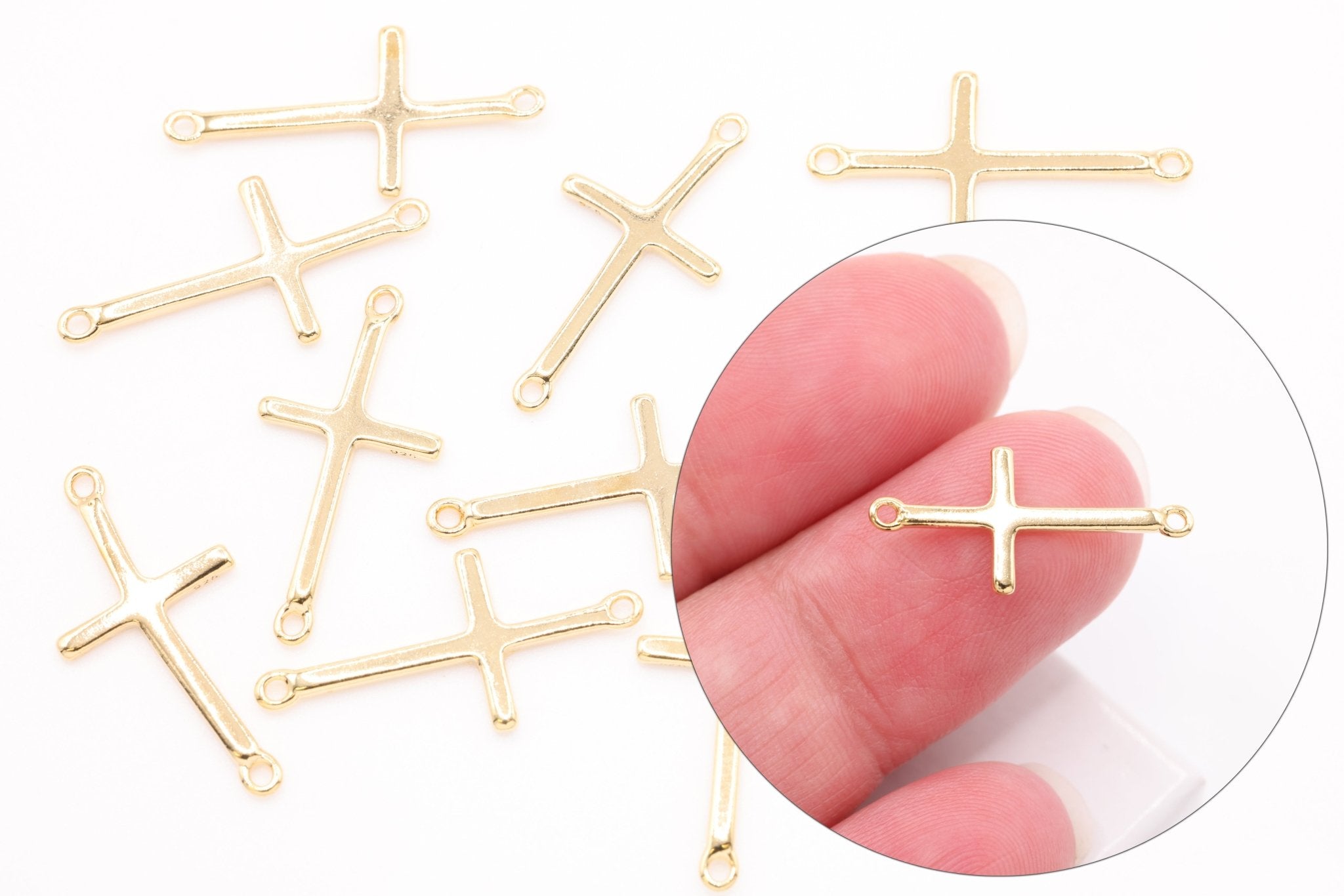

Gold-Filled

Gold-filled material uses a Zinc and Copper core to construct an inner material to support a gold exterior. Heat and pressure are used to make the gold alloy bond to the surfaces of the core. This is what it means when you see 12k or 14k, it means that the gold-filled process was used. These pieces and materials are great for use in broadly made designs, wholesale, or custom pieces. 14k gold is really great for everyday wear because of its durability, making it a great choice for jewelry makers and buyers. Customers love the fact that they’re buying high-quality material that won’t fall apart soon down the road.

Gold-Plated or Gold-Dipped

Gold-plated items have significantly less gold on them, but still maintain the integrity, quality, and longevity of the piece. They can have a slightly shorter lifespan as there is concern that the gold will wear off over time, but usually, these pieces are a great idea for the more budget-conscious side of gold purchases and are great to have as an option so that all dollar amounts are included in the array of products you carry.

Vermeil

Vermeil, by law, must have a base of sterling silver and contain at least two microns of gold alloy layered over it. Vermeil has a thicker coating of gold than gold-plating, but the material, as a whole, is still slightly less durable than plating itself. Still, however, a good option.

All in all, gold is such a great and versatile material to be working with. The quality of the element carries through to each variation from the pure form to gold-plated, you really can’t go wrong when it comes to quality. It’s more about picking what’s right for you and your platform. Gold is a luxury item, and tiers and choices to its range are great ideas to keep in mind as you move forward with purchases.

![Gold Filled Beaded Ring, Gold Silver Stacking Ring, Hammered Bead Ring, Gold Dot Ring Midi Ring Gold Filled Flat Beaded Ring Minimalist [30] - HarperCrown](http://www.harpercrown.com/cdn/shop/products/gold-filled-beaded-ring-gold-silver-stacking-ring-hammered-bead-ring-gold-dot-ring-midi-ring-gold-filled-flat-beaded-ring-minimalist-30-568879.jpg?v=1634159908&width=2048)

![Gold Filled Beaded Ring, Gold Silver Stacking Ring, Hammered Bead Ring, Gold Dot Ring Midi Ring Gold Filled Flat Beaded Ring Minimalist [30] - HarperCrown](http://www.harpercrown.com/cdn/shop/products/gold-filled-beaded-ring-gold-silver-stacking-ring-hammered-bead-ring-gold-dot-ring-midi-ring-gold-filled-flat-beaded-ring-minimalist-30-638411.jpg?v=1634159908&width=2048)